PRE-TREATMENTS

An excellent pre-treatment is necessary to achieve good adhesion in galvanic deposits, it is an essential first step to ensure a top quality result.

An excellent pre-treatment is necessary to achieve good adhesion in galvanic deposits, it is an essential first step to ensure a top quality result. Oils, grease, dirt or oxide layers must be completely removed.

ENERKEM

This is a range of universally applicable degreasers for chemical and electrolytic immersion steps on steel, brass, zamak, aluminium, iron and plastic. Products are supplied in concentrated powder or liquid form.

DERUST KEM

This is the complete range of universal pickling chemicals and additives for steel, iron, zinc die-casting and other non-ferrous metals. The processes are supplied as concentrated liquids or powders.

ANTI-CORROSION

Our anti-corrosion products offer the highest performance protection against iron corrosion in galvanised coatings and zinc alloys. With additional post-treatment, this protection can be significantly improved.

ZINKEM TECH is the cyanide-free alkaline zinc range for bright zinc deposits based on potassium or sodium. They feature excellent metal distribution and produce ductile, stress-free zinc layers even at high thicknesses, suitable for static and Roto-barrel applications.

ZINC-NICKEL; Thanks to our partnership with Schlötter Galvanotechnik, we offer the innovative SLOTOLOY ZN 80 VX and SLOTOLOY ZN 210 VX systems.

The formation of cyanide and organic decomposition products in the Zn-Ni bath is a well-known problem. With the new VX anodes, a special alloy patented and registered by Schlötter, these undesirable effects will be minimised and electrolyte efficiency will remain constant.

ZINKEM LUX is the range of acid zinc, a process that can be used both roto- and statically, imparts an excellent gloss and penetration to the deposit. The surfactants used give a stable mist point above 75°C. The surfactants used allow working with blown air, due to their low foaming power.

ZINKEM DIP PASSIVATION is the range of chemical passivation’s, which, applied as a post-treatment, impart greater corrosion resistance to coatings of zinc and its alloys.

ANTI-CORROSION

Our anti-corrosion products offer the highest performance protection against iron corrosion in galvanised coatings and zinc alloys. With additional post-treatment, this protection can be significantly improved.

ZINKEM TECH is the cyanide-free alkaline zinc range for bright zinc deposits based on potassium or sodium. They feature excellent metal distribution and produce ductile, stress-free zinc layers even at high thicknesses, suitable for static and Roto-barrel applications.

ZINC-NICKEL; Thanks to our partnership with Schlötter Galvanotechnik, we offer the innovative SLOTOLOY ZN 80 VX and SLOTOLOY ZN 210 VX systems.

The formation of cyanide and organic decomposition products in the Zn-Ni bath is a well-known problem. With the new VX anodes, a special alloy patented and registered by Schlötter, these undesirable effects will be minimised and electrolyte efficiency will remain constant.

ZINKEM LUX is the range of acid zinc, a process that can be used both roto- and statically, imparts an excellent gloss and penetration to the deposit. The surfactants used give a stable mist point above 75°C. The surfactants used allow working with blown air, due to their low foaming power.

ZINKEM DIP PASSIVATION is the range of chemical passivation’s, which, applied as a post-treatment, impart greater corrosion resistance to coatings of zinc and its alloys.

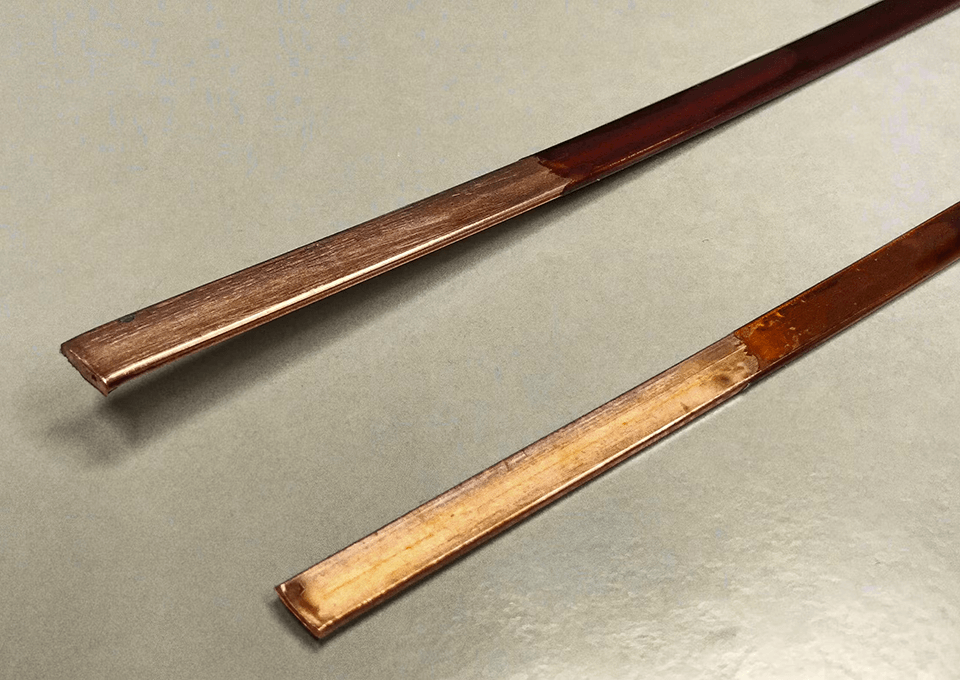

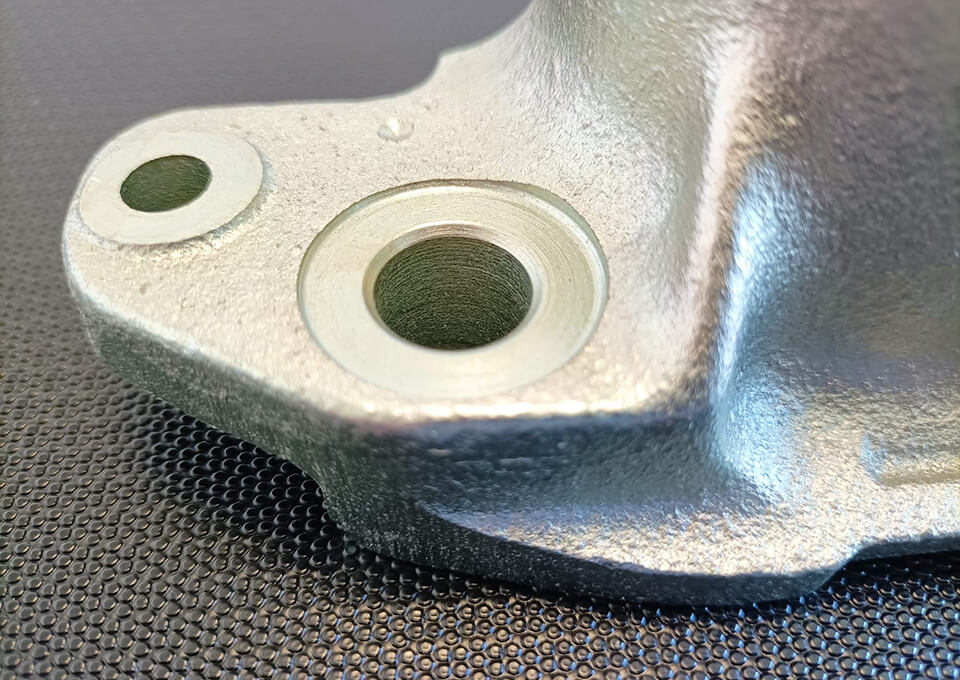

ALUMINIUM

The ALUXKEM line designed by KEMIA for the coating of aluminium alloys consists of special pre-treatments and a low-temperature chemical nickel-plating process. The ALUXKEM EN 520 process makes it possible to obtain an excellent coating with a nickel-phosphorus alloy (4-6 % phosphorus) with low thickness and high adherence, which means that the part subsequently treated with KEM TECH 430 cyanide-free alkaline copper plating, CUPROKEM 450 acid copper plating and our KEMALLOY WH350 white bronze process proves to be totally hypoallergenic according to tests carried out in accordance with UNI EN 1811:2011.

ALUXKEM line

ALUXKEM ACTIVE 20 chemical activation

ALUXKEM US 20 ultrasonic washing

ALUXKEM CH 20 chemical degreasing

ALUXKEM D/KAP 20 alkaline pickling process

ALUXKEM CMZ 20 single-component cyanide-free cementation

ALUXKEM CMZ 350 two-component cementation

ALUXKEM EN 520 low-temperature chemical nickel

DECORATIVE

Special attention is paid to the underlying coating processes that are essential to achieve the highest level of decorative effect, such as copper plating, nickel plating and, last but not least, an excellent high-performance white bronze process to meet the demand for nickel-free applications.

AUROKEM processes for the deposition of high-carat gold alloys with various colour shades.

AUROKEM BURNED processes for black gold plating to achieve vintage effects on gold and palladium finishes.

PALKEM processes for the deposition of palladium and its alloys.

RUTEKEM ruthenium deposition processes with a colour curve from L 70 to L 40.

PLATKEM deposition processes for platinum and its alloys.

SILVERKEM decorative silver plating processes.

ASTROKEM bright nickel plating processes.

KEMALLOY/BRONZOKEM high-performance white bronze plating processes.

CUPROKEM 450/260 acid copper plating processes.

CUPROKEM 420 cyan alkaline copper plating process.

KEMTECH 430 cyanide-free alkaline copper plating process.

TRIANON black and white trivalent decorative chrome plating processes.

DECORATIVE

Special attention is paid to the underlying coating processes that are essential to achieve the highest level of decorative effect, such as copper plating, nickel plating and, last but not least, an excellent high-performance white bronze process to meet the demand for nickel-free applications.

AUROKEM processes for the deposition of high-carat gold alloys with various colour shades.

AUROKEM BURNED processes for black gold plating to achieve vintage effects on gold and palladium finishes.

PALKEM processes for the deposition of palladium and its alloys.

RUTEKEM ruthenium deposition processes with a colour curve from L 70 to L 40.

PLATKEM deposition processes for platinum and its alloys.

SILVERKEM decorative silver plating processes.

ASTROKEM bright nickel plating processes.

KEMALLOY/BRONZOKEM high-performance white bronze plating processes.

CUPROKEM 450/260 acid copper plating processes.

CUPROKEM 420 cyan alkaline copper plating process.

KEMTECH 430 cyanide-free alkaline copper plating process.

TRIANON black and white trivalent decorative chrome plating processes.

PLATING ON PLASTICS

Polimers such as ABS, ABS-PC, PA and nylon can be plated thanks to a process named POP.

Kemia offers the entire process range to achieve this result.

KEMPLATE NEUTRALIZER M-180 neutralizer for exavalent chrome etching processes.

KEMPLATE SPEED range of speeding agents.

KEMPLATE CATALIZER X colloidal palladium process.

KEMPLATE CU Chemical copper plating processes.

KEMPLATE EN Chemical nikeling processes.

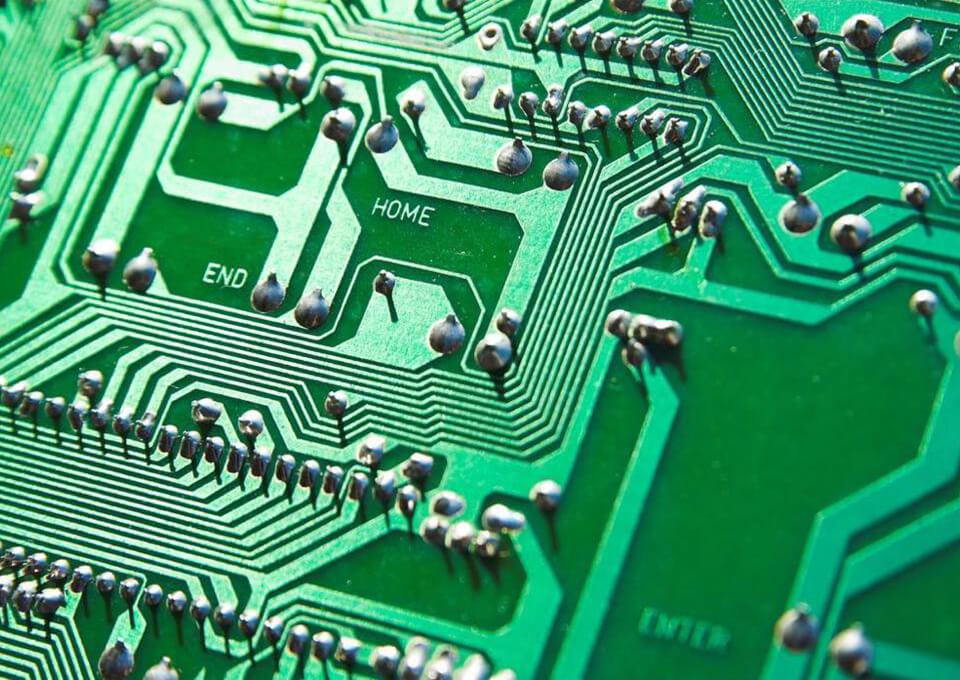

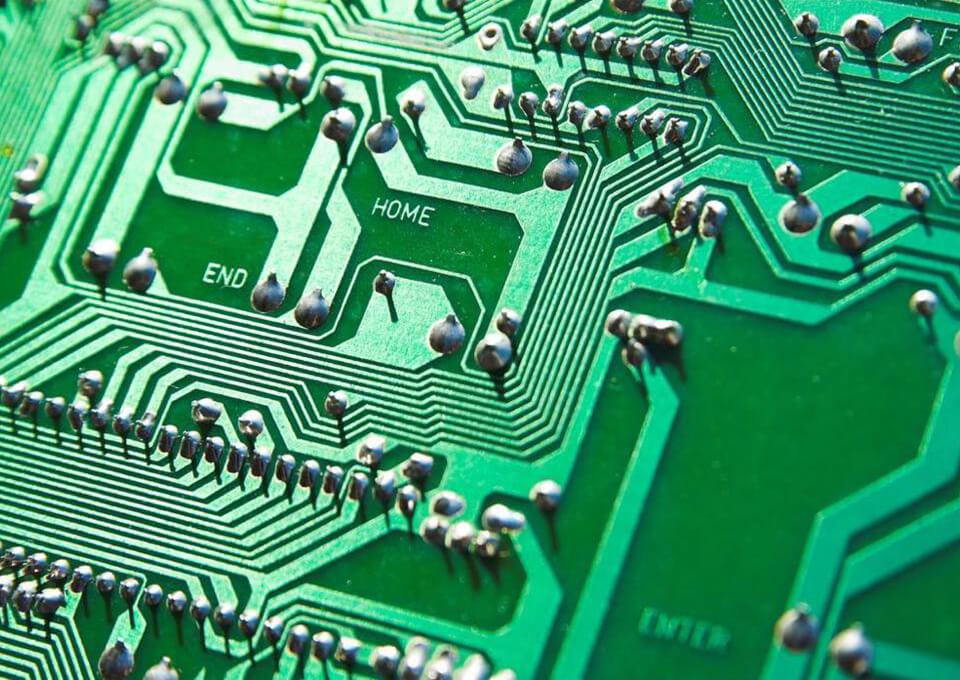

FUNCTIONAL ELECTRONICS

KEMIA’s wide range of processes ensures that all standards required by various industries are met.

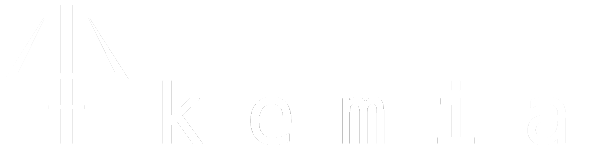

KEM TECH 430 Cyanide-free alkaline copper electroplating process with ductile deposits even at thicknesses of 50 µm – 100 µm.

NIKEM FLEX specific electroless nickel plating process for obtaining ductile and unstretched deposits.

TINNER Thanks to our partnership with Schlötter Galvanotechnik, we offer the methane-sulphonate tin plating processes of the SLOTOTIN series. These processes can be either bright or matt and have excellent solderability. They are also used in Reel-to-Reel processes, due to their excellent yield and the absence of foam.

TINKEM Acid tin plating processes based on sulphuric acid provide excellent brightness and uniformity at all current densities with excellent weldability. Thanks to our partnership with Schlötter Galvanotechnik, we have the historic CULMO process at our disposal.

EVOKEM Complete range of high-medium-low phosphorus nickel chemicals.

FUNCTIONAL ELECTRONICS

KEMIA’s wide range of processes ensures that all standards required by various industries are met.

KEM TECH 430 Cyanide-free alkaline copper electroplating process with ductile deposits even at thicknesses of 50 µm – 100 µm.

NIKEM FLEX specific electroless nickel plating process for obtaining ductile and unstretched deposits.

TINNER Thanks to our partnership with Schlötter Galvanotechnik, we offer the methane-sulphonate tin plating processes of the SLOTOTIN series. These processes can be either bright or matt and have excellent solderability. They are also used in Reel-to-Reel processes, due to their excellent yield and the absence of foam.

TINKEM Acid tin plating processes based on sulphuric acid provide excellent brightness and uniformity at all current densities with excellent weldability. Thanks to our partnership with Schlötter Galvanotechnik, we have the historic CULMO process at our disposal.

EVOKEM Complete range of high-medium-low phosphorus nickel chemicals.